Loading printed

labels and laminate into the DLF220S looks easy; right?

|

| DLF Media Path |

For me,

however, it’s not so easy. That’s why I

asked Tony Molina, our graphic artist to help me load the DLF220S.

In my post

about Sierra Stickers; I asked our

customer Derrick, “how long did it take to get comfortable using this label

finisher?” Derrick said “two weeks to

really learn how to use this finisher”.

And Derrick is a professional printer.

You should add to this time if you don’t use it every day.

Frankly, I’ve

avoided learning how to use the DLF as I’ll never use it every day. This post is designed to share some insight

into threading the DLF220S media path; and not to make you an expert.

|

| Load Printed Labels/Laminate |

First load the printed labels and

laminate onto the spindles and tighten the label core holder.

|

| Lock Coupling Roller |

Second, insert the labels into the

coupling rollers and lock the knob. Afinia suggests using the 2nd

hole from the left (which we didn’t do as shown by the picture above).

|

| Attach the Laminate |

Third, pull down the laminate with

both hands, centering it onto the label media. And then tighten the laminate

core holder. Make sure to adhere the laminate to enough of the paper area so as

to not have it come apart when you first advance it through the coupling

rollers.

|

| Attach Laminate |

Tony prefers to place the laminate

onto the guide roller to help smooth and center the laminate, then supporting

the paper from below against the guide roller to ensure easy alignment of the

laminate to the roll of paper.

|

| Advance Labels/Laminate |

Fourth, use the manual button to

advance the label and laminate. Be prepared for the noise of the laminate

coming off the roll.

|

| Under Damper/Into Rollers |

Fifth, run the labels under the damper

arm and up through the aluminum rollers. Adjust the edge guides to maintain the

media straight.

|

| Into Cutter |

|

| Align Edge |

Sixth, lift the handle or latch on the

rear of the plotter and push the media through the two pinch rollers. Align

the media by having the edge of the media touch the edge of the silver sticker

alignment points.

|

| Push Thru Cutter |

Seventh, move the pinch rollers to the

media edges on both sides. You can move them manually as long as the handle or

latch is up in the unlock position.

The entire surface of the pinch

rollers needs to make contact with the media surface edge on both sides.

|

| Close Lever |

Eighth, close/lock the plotter by

pressing down on the handle or latch securing the media.

|

| Select #2 |

Ninth, select #2 on the plotter

display.

Open the DLF software, and then from

within the DLF software open the PDF CUT FILE.

Measure the distance from the leading edge of a black mark to the

leading edge of the next black mark on the printed media. You need to be as

accurate as possible.

|

| Enter Blackmark Distance |

In the “DISTANCE BETWEEN BLACK-MARKS”,

enter the distance in mm.

|

| Advance Blackmark |

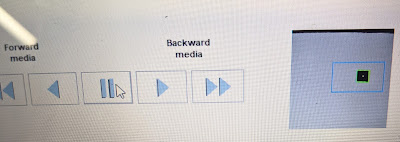

Use the forward media single arrow

button to slowly advance the blackmark into the camera square shown in the

software. The double arrow button advances the media much faster but is harder

to control. You want to align the black

mark in the center of the blue box as much as possible.

Prior to running a CUT TEST, check the

plotter knife using the loop that came with the DLF unit.

|

| Check Plotter Knife |

The blade should be set to hit the 3rd

mark from the bottom seen in the loop.

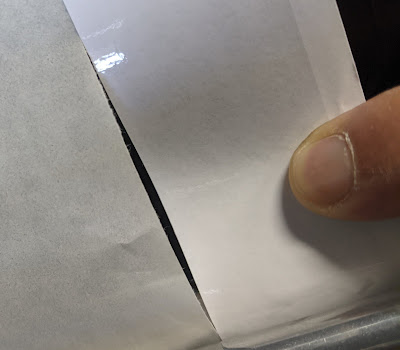

If the blade cuts the liner, change

the CUTTING FORCE on the DLF software. (You may need to remove the die-cut label

to confirm the cut depth. In this training session, we had to change the cut

force from 11 to 9. You can continue to do the cut test until the correct depth is found.)

|

| Cut Too Deep |

NOTE: At this

point, it is very important to remember that before you run a CUT TEST, the

Media Tension Control needs to be activated and set to AUTO. Then select CUT TEST.

|

| Activate Media Tension |

Eleventh, something that we didn’t do

in my training was to correct the offset in the software to make sure the label

is aligned with the die-cut. You can

move the cut in all directions; and then complete cut tests until aligned

correctly. My guess is we got lucky. We

didn’t have to correct the offset in our training session because the label

aligned with the die-cut line perfectly after our first cut test.

|

| Adjust Media Offset |

Once completed, select “COPY MODE ON”

to preselect the number of copies you want.

At this stage, we still wanted only a few to ensure the cut is correct.

Now we get into the hard part of the

media path (at least I found this part difficult).

|

| Place Thru Rollers |

Twelfth, run the media down through the aluminum

rollers. Adjust the edge guides to

maintain the media straight.

|

| Thread Under Damper |

Thirteenth, run the labels under the second

damper arm and up and over the thick aluminum roller, down and under the thin

roller as shown on the photo below.

|

| Place Over Roller Into Slitter |

Fourteenth, place a core onto the

waste rewinder; then the pull off the waste matrix once the labels are fed

under the roller and connect it to the core.

|

| Connect Waste Matrix To Core |

Then you can push down the waste

press. And then close the sponge roller. I’ve seen users run the waste from the

outside edges into a garbage can; or can be connected to the waste roller.

|

| Attach To Core |

Fifteenth, connect the die-cut labels

to the core(s) on the rewinder making sure the label media rewinds evenly.

Sixteenth, position the slitters in

the correct positions on the sides, and in cases where you are die-cutting

multiples labels across the media, you would position the slitters in between

the labels as well.For this, you may need to purchase

more slitters.

At this point you need to TURN ON the

Waste Remover.

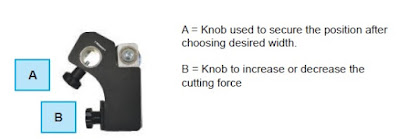

Seventeenth, If needed, you can set

the backslitters which also cut the outside edges of the finished label media correctly. Frankly, this step seemed the most difficult

to me as you have to work behind the media path. Knob “A” moves the backslitter; knob “B” sets

the cut depth.

|

| Set Backslitter |

Eighteenth, Lock

the backslitter lever in place by placing the pull-pin on the left side hole.

(the backslitter lock pin-hole on our DLF needs some work).

After all of

these steps, you can run the job.

And here is a video of the DLF220S cutting Circle Label.

To see Afinia’s

official directions, download the DLF-220S User Manual here:

In this simple

stepwise recommendation, I attempted to make a relatively complicated process

easy. It doesn’t include possible

adjustments required to get the die cut exactly correct; or how to set up the

art/cut file. But I hope it helps you

speed up the process of becoming comfortable running the DLF220S. And help you reduce the waste produced in

training to use this machine.

Tony says, "No doubt, the DLF2220S is a great tool to have at your disposal

when laminating custom-size die-cut labels. Once you get past that

learning curve that every new user has to experience, the DLF220S will produce

beautiful custom die-cut labels. Compare to other large format printers,

this puppy is relatively fast, compact, and easy to use. Again, once you figure

out how everything works and you get the machine dialed in, the sky is the

limit for creating any shaped-size label"

I’m lucky to

have Tony work with me/us on the DLF220S.

He was very patient with me; and a lot of help.

Together with

the L801, the DLF220S can help you make the labels you need, when you need

them; and at some of the lowest costs available. If you need to make a lot of different

labels, contact us to learn more about the DLF220S.

Guy Mikel

855-962-7670

No comments:

Post a Comment