At Pack Expo this past week, Epson demonstrated a new, benchtop, on-demand color label printer scheduled for release late spring 2012. Currently code-named Shiraito, this new printer produces color labels at 10 to 12 inches per second, uses 4, large, color cartridges and includes a built-in cutter. This new printer produced beautiful color labels; very quickly.

In addition to Epson, I understand another company, with a print engine, has OEM customers who will release fast, on-demand color label printers. Imagine; soon you will be able to print labels with color pictures, graphics or logos as fast as current high-end black-only thermal transfer label printers.

With the availability of these new on-demand color label printers, I wondered; how will this new technology impact the $2 billion global barcode printer market? Or the $55 billion global label business?

At this point in time, some people believe that color will have little to no impact in the world markets; until the cost per label becomes cheaper than black only/monochrome. I hear the statement all the time; “I'll consider color when the cost per label is less expensive than thermal transfer.” Cost seems to be the only decision-making criteria for some people.

I have a different perspective; on-demand color will make a big change in both the label and barcode printer markets for five reasons. First,

color has made a significant impact in other peripheral device markets. In the related page-printer market, color accounted for

44% of the printers sold globally in 2006 (

http://www.gartner.com/press_releases/asset_145732_11.html). In another related market, copiers, color accounted for approximately

20% of the units (and probably much more of the revenue) of the global copier market in 2008 (Garner Dataquest). If these two markets can move to a significant degree to color, I see no reason not to expect the same results in the barcode label printer market.

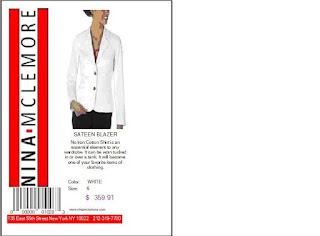

Second, adding color to existing labels will increase the readability of labels. Labels are the one document most customers and supply chain members must read/scan. “Nobody reads black print anymore” was a statement I heard just the other day concerning labels. If your customer wants to insure key information is communicated on a label, you should consider adding color pictures, icons, logos, and fonts. These devices insure critical information is communicated. In addition, the look of a label is significantly improved by the addition of color. Ask yourself: which are these labels look better?

Third, innovative customers and value added resellers are creating new solutions to help their work processes. These new processes will make companies more productive and position them more professionally. Keep up with my blog to learn about new applications and solutions using on-demand color label printers.

Fourth, on-demand color labels will enable companies to

establish new business models. For example, Catalina Marketing, an Epson partner, produced $500 million in revenue (

http://www.catalinamarketing.com/pdf/Smart%20Business%20Magazine.pdf) in 2008 by publishing on-demand color coupons at checkout in grocery stores. Imagine the impact to the barcode printer market if just one of the shipping companies (FedEx, UPS, etc.) started using color label printers to publish or enable on-demand advertising on the packages they ship. Or if a major online retailer such as Amazon, Wal-Mart, etc. started adding or enabling special offers to the packages they ship. Shortly, an organization will find the means to monetize publish on-demand labels.

Fifth, printers will convert short-run label production to the on-demand label printers. Many small manufacturers need a small number of labels for a high number of SKU’s; especially considering SKU proliferation and globalization of products. Today, many of these short-run labels are produced using a digital press which requires extensive setup time. In the near future, service bureaus will be able to fulfill these short-run orders much less expensively and faster than a digital press using high speed, on-demand, 4 color label printers. Therefore, a portion of the $55 global label business will move to the barcode label printer market.

Bottom line: on-demand, benchtop, color label printers will make a very positive impact on the business of value added resellers and independent software vendors like you. Now is the time for you to become an “expert” in this market.

Be sure to sign up on my blog; and let me know your thoughts on this market opportunity.

Guy Mikel