I am pleased to

announce that the Colorworks Label division of Epson has been named co-winner

of the AIM “Organization of the Year” award.

I mention this

award for two reasons. First, they

deserve the recognition for the contributions to automatic identification and

label printing. And second; because I nominated

them.

Why you ask? Below is the nomination recommend that I sent

to AIM.

For the AIM

2020 Organization of the Year, I’d like to nominate Epson America for their

success with on-demand color label printers.

This nomination results from Epson’s successful efforts to move from

monochrome only barcodes to labels with colors and images. Let me tell you a bit more about Epson’s

generations of products and markets on-demand color printers serve.

Since the

decade of the 2000’s, Epson has launched 6 generations of automatic

identification, color label printers:

|

| Catalina Printer |

With the launch in the mid 2000’s, the Catalina

printer became the standard for printing coupons in groceries across North

America. Hundreds of thousands of these coupon printers were deployed, each

producing coupons with barcodes.

On-Demand color

label printers are changing the way companies produce labels. All of these

examples use color and barcodes to help their internal employees, customers and

regulators identify quickly the correct products. Some of the market applications include the

following segments:

Chemical:

As mentioned previously, GHS and the need for color, variable pictograms

jump-started the market for color label printers. With the Epson printers, chemical

manufacturers could print variable data, barcodes, images and pictograms

on-demand. Because of the capability to

meet the GHS requirements, Epson printers became the de-facto standard in the

chemical industry. Here, our customer NIC, produces great looking GHS labels:

Manufacturing:

Companies producing a large number of SKU’s or organizations needing to produce

variable images for retailers such as Home Depot and Lowe’s, need to manage

their label inventory. Print on-demand

color makes it possible to reduce waste and manage label inventory. Here is a good example of how manufacturers meet this requirement:

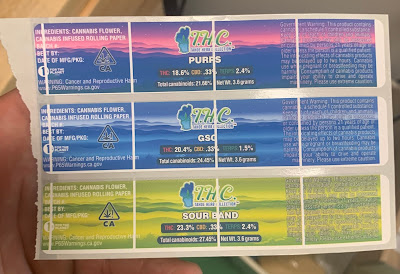

Cannabis:

With the need for variable data such as THC content and Lot Numbers; as well as

the importance of branding, Cannabis manufacturers have moved to print

on-demand color labels. Given the legal

requirements and the large number of strains/products, cannabis companies

prefer generally, on-demand color labels; including cultivators like 14er's.

Plus. companies in many other markets are benefiting from on-demand color for their labels with barcodes.

Finally, color

label printers existed prior to the launch of Epson’s printers. And many other color label printers have come

into the market. However, Epson has

focused most of their innovations on printers designed for the automated

identification segment of the label market.

Their printers fit this business.

Overall, color

label printing has been the largest and most important innovation to automatic

identification technology since thermal printers. And Epson’s technology for durable and

affordable labels and printer hardware has made this happen.

Guy Mikel

855-962-7670