All the time, we get requests for Kraft paper labels.

However, I’ve found these Kraft labels to print poorly with inkjet

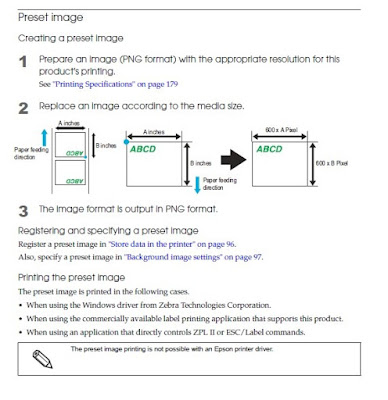

printers. The primary reason for poor

print quality is that the ink will migrate/spread on plain paper. This migration or spread makes the print

quality look “fuzzy” and frankly, not good.

Wish I had a closeup picture; so hopefully you can imagine what I mean.

Almost all of the labels we sell have an inkjet coating. This coating adheres the ink to the surface

of the label, preventing the ink from migrating/spreading; and making the ink

bind to the paper stronger. For example,

inkjet coating enables us to sell durable, poly labels that meet the BS5609

requirements. To meet the requirements

for the marine shipment of chemicals, printed labels must survive in the ocean

and resist server abrasion testing. Learn

more about BS5609 from these older posts here:

Now we have just launched a new inkjet coated Kraft paper label that

prints great!

|

| Inkjet Coated Kraft Paper Labels |

When we received the new inkjet coated Kraft paper, we printed the

material using a relatively low-resolution artwork.

|

| C3500 Printed Inkjet Coated Kraft Labels |

And compared it to our standard matte paper:

|

| Matte Paper vs Inkjet Coated Kraft Paper Labels |

From our print tests, we found the print quality of the new inkjet

coated material much better than traditional Kraft paper labels and almost as

good as our standard matte paper labels.

Once tested, we sold it almost immediately to a customer, Kristy of

Blue Rock Acres.

When asked why Blue Rock Acres was interested in a Kraft paper label,

Kristy said, “The company was looking for a label that would distinguish our A and B Brands.

We went with Kraft-backed packaging for the new B brand and thought the look should

carry over to the label as well. We wanted a brown bag appearance, a wholesale

or low-price vibe, while still being eye catching to the consumer. I think the

Kraft labels capture this extremely well and I am very pleased with the new

labels.”

|

| Blue Rock Acres Printed Labels |

Considering

these labels were printed with a relatively low-resolution C3500 printer, I

think they look great! According to

Kristy, “The new Kraft labels look great and print great, including small print

disclaimers and barcodes! Just the look we wanted.”

If you are

looking for vintage or brown paper look for your labels, consider our new

inkjet coated Kraft paper. You’ll find

these labels print great; and convey the desired brand image.

Guy Mikel

855-962-7670