Beverly Hospital is a not-for-profit, leading and independent 224-bed

acute care facility that is proud of the medical services and comfort provided

to patients. From emergency room and hospitalization to outpatient procedures,

Beverly Hospital offers a full range of services with the latest technology;

including the pharmacy.

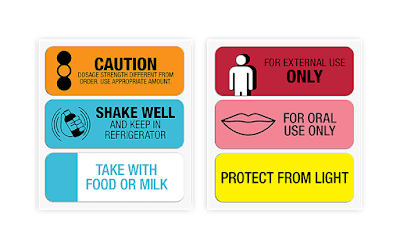

Beverly Hospital, like other small to midsize hospitals in the United

States, processes about 2000 prescription orders per day. About 250 of those orders or prescriptions

require instructional color labels such as “Look-alike

Sound Alike”, “For Oral Use Only”,

“Protect From Light”, and “Shake Well and Keep In Refrigerator”. Wayne Campbell, Director of Pharmacy of

Beverly Hospital says, “we get these auxiliary labels from 4 different label

manufacturers. Sometimes we’d get them in a timely fashion; sometimes we don’t. We don’t know who ordered what from whom or

when it’s coming in. It’s very

challenging”.

To

improve this situation, Beverly Hospital deployed the ClariSafe Color Label Solution

from Addmaster, https://www.addmaster.com/product/clarisafe/, with partners HP, and Neenah Paper.

Addmaster has over 30 years of experience developing and manufacturing inkjet

printers for the financial market with over 300,000 printers installed

worldwide. John Clary, VP of Engineering at Addmaster, decided to develop

an inkjet color printer with a small footprint and software that mimics

pharmacy personnel ordering from a catalog to print the color labels they

need when they need them.

|

| ClariSafe Printer |

“ClariSafe™ can print all of my labels on-demand, any time I need

them. It prevents overstocking. It prevents us from running out of labels and

enables us to make special labels that are not available on the market” says Wayne.

|

| ClariSafe Label Catalog |

According to Alex Shafer, Director of Business Development for

Addmaster, “The ClariSafe Color Label System costs $1,495 and includes both the

printer and application to print durable color labels when needed. Plus we’ve added and will continue to add labels in

the catalog as hospitals want and need more secondary artwork to print.”

As

you may remember, I’ve written about ClariSafe before: https://colorlabelsondemand.blogspot.com/2016/11/new-option-for-pharmacyanesthesia-labels.html

To

purchase the ClariSafe Color Label Systems, visit our store:

To

purchase ClariSafe ink, visit out store:

https://colorlabelsolutions.com/product/clarisafe-tri-color-inkjet-cartridge-97262/

For

pharmacy managers, ClariSafe is a great option to simplify secondary/auxiliary labeling. This

system eliminates purchasing a large inventory of labels, enabling you to print

what you need, when you need them; with a very small footprint device. Contact us if the ClariSafe Color Label

Systems may fit your pharmacy operation.

Guy Mikel