When first speaking, SPARC was looking for a lower cost method to label

their products. According to Justin

Morgan, IT Director at Sparc,

“We were purchasing 5 different versions of preprinted

labels from our

bag vendor; and wanted a lower cost means to color code our products. Color-codes are important for us and our

customers. We use the color codes in

both our labels and menus. The colors

differentiate the genetics of our different strains of cannabis. Purchasing 5 different kinds of bags was

expensive in the quantities we were purchasing.

Our hope was to get lower prices by purchasing larger volumes of single white bag;

and printing custom color labels to affix to them.”

After understanding the requirements, I printed and sent samples to

Sparc to test.

|

| SPARC Sample Label |

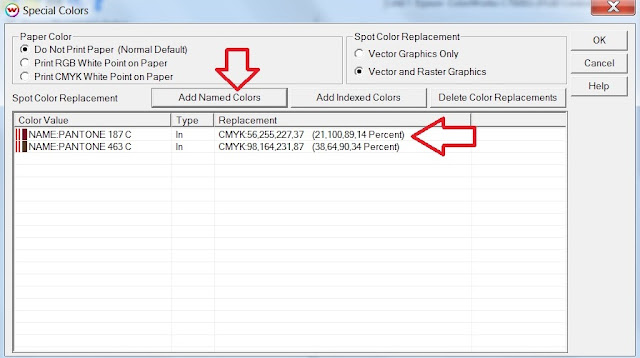

Based on the recreated label format, I estimated the ink cost at

$0.002/label. In addition, I calculated

the costs of continuous labels at $0.005 each.

The overall costs of these labels were much less than 1 penny each.

After hearing the estimated costs, Sparc decided to test the

C3500. We sent them a demo printer to

run with the label application, BarTender.

Justin said, “we used BarTender to add the variable data in black print

to our labels. To run the C3500, we just

recreated the label template adding a variable image field to the existing

label and database.”

|

| Sparc Test Labels |

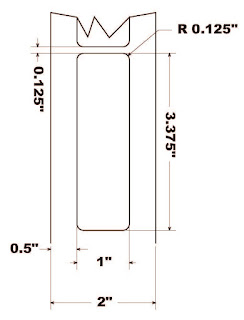

As a first draft, the BarTender label template was not perfect; with

some of the print off the edges of the label.

Working with Justin, we got the labels centered by taking into the

account of the .06” non-printable boundary.

With the new drivers, you can print to the edge of the labels.

|

| Sparc Finished Label |

Based on this work, Sparc purchased a C3500 and gloss paper

labels. Since the initial purchase,

Sparc has added matte poly labels for their smaller vials. “We needed the poly to work with the small

circumference packaging”, says Justin.

The poly labels are more conformable with less memory than paper. These advantages make the poly labels perform

better for tighter wrapping applications.

|

| Sparc Finished Label |

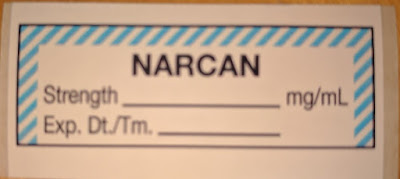

In addition to the color-coded finished good labels, Sparc need a means

to track their plants in production.

Justin says, “we were hand writing up labels for our individual plants;

and we needed a less labor-intensive means for their work.” Based on this requirement, we sold Sparc a

thermal transfer printer and “Pot Stakes” to track their production.

|

| Printed Pot Stake |

“Using the pot stakes are much easier and faster than the hand labeling

we were doing previously” says Justin.

|

| Sparc Finished Label |

Justin says, “overall, I’ve found the label printing solution

incredible; especially the BarTender integration. Also, we’re very happy with the quality of

the print. We’ve found a large cost and labor savings providing a great return

on our investment in the label printers and software.”

|

| Sparc Labels |

And

from a long time ago, a post covering our long-time customer Green Ticket

Bakery who now has upgraded to a C3500 to print their labels: http://colorlabelsondemand.blogspot.com/2012/06/baking-medicinal-brownies-printing.html

We love and support all of our customers; but we especially appreciate long-time customers such as Sparc. If you need labels for your cannabis products; or need color coded

labels to improve your work processes, contact us. We can help!

Guy Mikel

855-962-7670