This week, I had the opportunity to get a “Sneak Peak” at an exciting

new technology coming this fall.

|

| C7500G Printed Using a RIP |

If

you attended Pack Expo in Las Vegas last year, it may not be so new. Epson America and Wasatch Computer Technology (https://www.wasatch.com/softripmain.html) demonstrated

an early prototype of a RIP (Raster Image Processor) for the C7500. Since Pack Expo 2015,( http://colorlabelsondemand.blogspot.com/2015/10/pack-expo-2015.html), these two companies have made significant changes to their early

prototype. Let me tell you more.

As background, a RIP is defined as “a

hardware or combination hardware/software product that converts images

described in the form of vector graphics statements into raster

graphics images or bitmaps.”

According to the Epson technician that demonstrated the new software, “the

Wasatch RIP enables you to control the colors and amount of ink over your

entire label. This control enables you to

match colors precisely; and to automatically replace colors with the corrected

RGB or CMYK color. Overall, the Wasatch

Rip enables much better print output; like much more expensive label printers

provide.”

The image above was printed using the RIP on the C7500G on gloss

paper. Based on this print output, I

believe the C7500G will produce outstanding/beautiful labels. And print these images easily, reliably and

more affordably than any other on-demand color, digital printer.

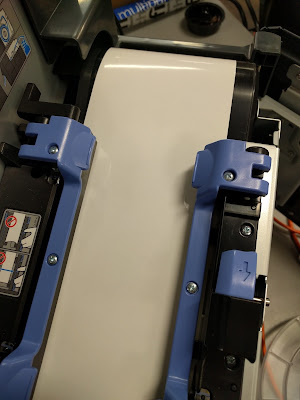

In addition to managing color, the Watsch RIP and updated firmware will

enable the C7500G to print on continuous label material. Currently, the C7500G requires either die cut

or blackmark labels. See these labels in

the C7500G using the updated firmware don’t have either means to find top of

form.

|

| C7500G Using Continuous Labels |

|

| C7500G Using Continuous Labels |

By

combining the RIP software with continuous media, printers and manufacturers

can produce full-bleed digital labels using the same workflow as companies

running million dollar presses. By

printing the label on continuous media; and then using a post-printing finishing

process to die cut and then laminating/coating the labels. In this video, I feature the Scorpio+

finishing unit from DPL that shows the machine laminating, die cutting and

weeding the matrix from the label to produce professional grade labels easily. https://www.youtube.com/watch?v=FiVD74MtD4I

I see the new RIP and continuous capabilities of C7500 or C7500G

combined with a finishing unit as a great option for printers, converters or

larger manufacturers with print shops who want to produce their own professional,

full-bleed labels. It’s a very low cost

way to produce short-run digital labels.

Epson says they will show the new RIP and

continuous capability at Label Expo this fall.

Learn more about this show here: http://www.labelexpo-americas.com/. I attended two years ago; and will attend again this year on September

14th and 15th, 2016.

If you are attending, let me know so we can meet.

If you are a printer, converter or manufacturer with a print shop,

contact us to discuss how you can use the C7500G and the new RIP to expand your

business or improve the look of your labels.

Guy Mikel

855-962-7670

No comments:

Post a Comment