Does your

company have sustainability goals? Are

you concerned about sustainability?

|

| Sustainable Label Production |

If the company

wants to use environmentally sustainable methods of production, you may want to

review your labeling process. This post

outlines how changing one type of labeling method may make your labeling

process much more environmentally friendly and help meet the United Nations

Sustainable Development Goals.

|

| On-Demand Color Label Sustainability |

- Commercially printed labels

- Inhouse Thermal Transfer printed labels

- Commercially printed “Shell” labels with variable data added with a thermal transfer printer

- Inhouse On-Demand color inkjet labels

These 4 different printing methods would seem to account for the vast majority of labels produced each year. As you can imagine, these different methods produce a different impact on the environment. Epson published this paper outlining how on-demand color inkjet printing offers a more sustainable method for producing labels.

And

get the report by Smithers here:

|

| Label Sustainability Comparison |

This study

concludes that by moving to on-demand color inkjet labels, companies would make

major progress toward printing labels in a sustainable method and reaching the

United Nations Sustainable Development Goals.

Especially SDG

7: Affordable and Clean Energy

Inkjet printers

are a far less energy intensive process

SDG 9: Industry,

Innovation and Infrastructure

Inkjet printers

can reduce waste of materials and stock obsolescence

And SDG 12:

Responsible Consumption and Production

Inkjet printing

reduces waste materials significantly (ribbons)

Let me tell you

how changing your labeling process makes your company more sustainable in 3 key

areas.

Energy

|

| Inkjet Energy Savings |

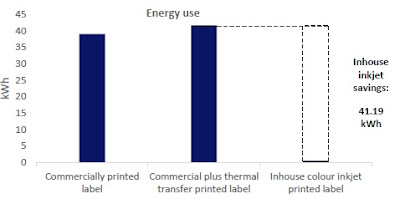

Energy

consumption differences between the different label printing methods are

extreme. On-demand color inkjet uses approximately only 1% of the energy to

print labels compared to commercially printed labels or commercial plus thermal

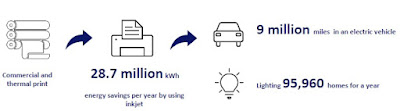

transfer printed labels. In fact,

Smithers calculates that if the European market would move from these

commercial/thermal transfer methods of label production to on-demand color, the

energy savings would power 95,960 homes for 1 year.

|

| Inkjet Energy Savings |

As the economy

of the United States is approximately 1.38X larger than the European Union, the

energy savings would be even larger here.

Therefore, moving from commercially printed “shell” labels with thermal

transfer variable data to inkjet labels would save enough energy to power probably

over 132,000 homes for 1 year. The

energy savings is significant by moving to on-demand color. For me, this energy

savings is the most important aspect as it enables reduced CO2 impact from labels.

Waste

|

| Inkjet Label Waste Savings |

For Jacob

Kallergis, Product Manager for Epson Europe, label waste is most

important. You may remember my recent

post on food certifications based on information provided by Jacob.

According to

Jacob, “I find the amount of

waste from preprinted and thermal transfer labels as most important. When

trying to save and reduce costs, wasted labels

are usually one of the elements most companies ignore when doing a cost

analysis.” 25,264 soccer fields of

wasted labels each year sounds terrible.

In the United States, this number would exceed probably 30,000 soccer

fields.

|

| Wasteful Label Inventory |

According to the Smithers study, up

to 11% of preprinted labels are wasted; from start up, make ready or

misprints. Further, preprinted label

inventory obsolescence is a major waste factor, with Smithers reporting that up

to ½ of stock labels for certain brands go bad each year.

Ink And Consumables

|

| Thermal Ribbon Waste |

In

addition to energy consumption

and label waste differences, ink and consumables represent another major difference

between thermal transfer and inkjet label printers. For every square inch of

labels printed by a thermal transfer printer, a square inch of wasted ribbon is

produced. In Europe, the equivalent of

41 double-decker buses of waste ribbons are produced each year. And a lot of extra ink is wasted. At the same time, Epson recycles a large

number of inkjet cartridges; and so can you.

Read more here.

Looking at Storage & Transportation

as well as Release Liner, Smithers found no real differences. The entire label industry, however, must find

ways to reduce the amount of liner wasted.

|

| Inkjet CO2 Reduction |

Overall, Smithers calculates that moving

to On-Demand Color Labelling from Thermal Transfer and Commercial Printing in

Europe would reduce CO2 emissions by 6.7 million tons. And this number in the United States would be

much higher; probably over 9 million tons.

In the report, Ciaran Little VP, Information Division from

Smithers, says “On-demand inkjet color label printing is often now the most

sustainable and operationally efficient choice.”

When asked, why

did Epson complete this project with Smithers, Jacob said, “It is our strategy

to promote not only on-demand color labelling as a method for sustainable label

production, but also increase awareness of this process overall.” Further I asked Jacob, is this research and

the finding believable? Jacob said, “Smithers carried out the analysis

independently, using public available data. As Smithers is a reputable,

independent organization, they have a great wealth of knowledge on labeling. And

their impartiality isn’t disputed. They work with most companies in the

labeling industry, and would not want to risk their reputation.”

In the past,

I’ve written many times about why and how to move away from thermal transfer to

inkjet label printing. Recent posts include the following.

But the impact

on sustainability seems to be the most logical and strongest reason to move

from thermal transfer to inkjet label printing.

If you are an enterprise company with a sustainability program; and/or

if you have banks of Zebra or other thermal transfer printers in manufacturing

plants, distribution centers or warehouses; then consider moving to inkjet label

printers. You’ll help the environment;

and help your company meet their sustainability goals. Contact us if you want to print labels more

sustainable.

Guy Mikel

855-962-7670

No comments:

Post a Comment