GHS is an acronym for The Globally Harmonized System of Classification and Labeling of Chemicals. Adopted by the United Nations in 2003, GHS is a system for standardizing and harmonizing the classification and labeling of the $1.7 trillion global chemical business ($450 Billion in the US

- Defining health, physical and environmental hazards of chemicals

- Creating classification processes that use available data on chemicals for comparison with the defined hazard criteria; and

- Communicating hazard information, as well as protective measures, on labels and Safety Data Sheets (SDS).

For a detailed explanation of these new requirements, please review this OSHA document: http://www.osha.gov/dsg/hazcom/ghs.html

Prior to GHS, regulatory bodies around the world required different looking labels that led to confusion with workers and emergency personnel. Even in the US

Under GHS, label elements have been standardized:

- Symbols (hazard pictograms): Convey health, physical and environmental hazard information, assigned to a GHS hazard class and category. Many or most of these symbols or pictograms must be printed in COLOR. (see figure 4.9 in the above link).

- Signal Words: "Danger" or "Warning" are used to emphasize hazards and indicate the relative level of severity of the hazard, assigned to a GHS hazard class and category.

- Hazard Statements: Standard phrases assigned to a hazard class and category that describe the nature of the hazard.

Previously, companies could produce preprinted labels with a variety of pictograms and use a thermal transfer printer to cross-out those symbols that were not required for the chemical. Under GHS, this practice is not allowed.

One key aspect: Transport pictograms are different in appearance and size than the GHS pictograms. You don’t need to include both in a single label. Therefore, labels smaller than 8.5” wide will work.

As for implementation, countries are implementing these standards at different rates. In the USA

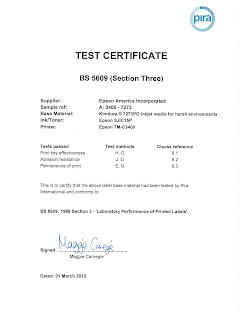

As merchant shipping transport most international shipments, chemicals manufacturers are obligated to label their products with materials that meet BS5609. British Standard BS 5609 is a specification for printed pressure-sensitive, adhesive coated labels for marine use which includes requirements for the label base material.

To meet the GHS requirements, companies have two options: Purchase preprinted color labels that meet the BS5609 standard for each product, requiring companies to maintain an inventory of labels or produce them just-in-time with a color label printer. By producing color labels on-demand, chemical companies reduce inventory, reduce waste, reduce the time to pick and putaway labels, simplify work processes and reduce their overall labeling costs.

To produce color labels on-demand, some chemical companies have decided to use color laser printers. These printers cost significantly more to operate; and most allow only sheet fed, 8.5” x 11” options.

Now, chemical companies can use the Epson TM-3400 ink and the Kimdura poly inkjet labels from Neenah Neenah

With the implementation of GHS, contact your chemical company customers to discuss their deployment plans for GHS labels. Recommending the Epson TM-3400 and BS5609 certified media, you can support their efforts to meet this important, new standard.

Guy Mikel