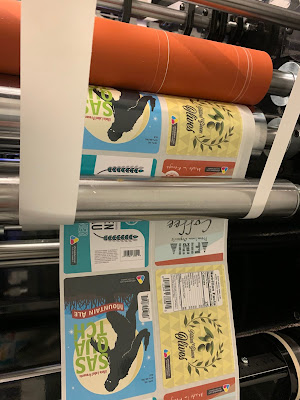

Recently, we

deployed our first DLP-2100 Digital Label Press from Afinia:

|

| DLP-2100 Label Press |

Watch the

DLP-2100 press run here:

And learn more

about the DLP-2100 from Afinia’s website:

Tony Molina, our graphic artist,

participated in the deployment.

According to Tony, “The DLP-2100 is fast, compact, precise and a workhorse

of a machine”. At first glance, he thought setting up the DLP-2100 seemed very

daunting and complicated. To make it

easy, Afinia placed a digital diagram on the DLP-2100 press control panel that

shows you the paper path you need to follow, so loading up the paper throughout

from beginning to end seems relatively easy to accomplish. After

watching Paul Lueders from Afinia finish the training session for the day, Tony’s

final thought was... “all these moving parts feel very synchronized and the

entire unit runs very smooth. The finished die-cut labels look fantastic. Wow!

this machine is very impressive!”

|

| DLP-2100 Rotary Press |

When asked, what

is the most difficult aspect of operating the DLP-2100 press, Tony said, “Learning

and navigating through all the functions on both the L901 printer and the Press

touchscreen panels.

You can operate

them simultaneously or independently from each other.”

|

| DLP-2100 Die Cut Label |

When ask about

the main benefits of the DLP-2100, Mike Atkins, National Sales Manager for

Afinia Label, said “The DLP-2100 has many benefits. It features flexibility,

speed, print quality, and more. I believe the best benefit, during the current

business climate, is controlling the supply chain for your packaging. We have

seen higher pricing and slower delivery from label manufacturers in the United

States. And companies who were outsourcing printed labels from Asia are now

finding it very difficult to get them in a timely and cost-effective manner. I

think we will see a trend of companies bringing labelling in house as part of a

larger strategy that lessens reliance on the uncertainty around the supply

chains.”

Watch Mike in a

video on the DLP-2100 here:

To make sure a

deployment of the DLP-2100 works well, Mike says, “I find companies who

successfully implement an in-house digital press focus first on training.

Identify a project lead to operate the press, and give them some ownership of

the project. Also, it is extremely important to train at least 1 if not 2 back-up

operators. If digital label printing is going to become a mission critical part

of your manufacturing, make sure to have a few people able to operate and

maintain the press."

I asked Mike, what skills are

important to operate a DLP-2100 press?

He said, “First, have access to a graphic designer. This is not just for

designing great looking labels, but also for setting up the artwork to match

the die, making minor tweaks in the designs, and creating the artwork required for

ordering new, custom dies. Finding an operator with some press experience is a

plus, though not entirely necessary. When selecting an operator, find someone

who has well developed mechanical skills, with the eye for detail to maintain

the press routinely. Keeping the press clean and free from adhesive build up or

dust will help ensure maximum up-time.”

After running the press, the most

important question I asked Mike; what companies should consider purchasing a

DLP-2100. Mike said, “A private label

manufacturer is our main customer for the DLP-2100. Because the DLP-2100 uses

dies to cut labels at high speed, every size will require a custom

made die. Dies are not expensive, around $150-$200 on average. But they do take

about a week to order. Contract manufacturers, and white label packagers typically

use a small range of containers, and therefore, do not require a large number

of dies. The DLP2100 is extremely fast,

easily capable of producing tens of thousands of labels per hour.”

If you produce

a large number of a limited size of labels, you should consider the

DLP-2100. You’ll save money on labels,

improve your supply chain and give manufacturing great flexibility to meet your

customer’s demand.

Contact us to

learn more about the DLP-2100 and how we can help with the deployment of this

large volume digital press.

Guy Mikel

855-962-7670