|

| Existing Shakti Labels |

Recently, Shati decided to change the label

printing/application process. According

to Ryne O’Donnell, Founder & CEO, “We wanted to move to

a label printer and applicator in house so that we could quickly change LOT#,

Expiration Date and Organic Certification Information on our labels.

|

| Existing Shakti Labels |

In addition to changing their label

production process, Shati wanted to change their label design as well. Ryne says, “We decided to have our labels

redesigned so that we could easily open PDF files from a workstation and print.

It’s important to change the LOT# and

Expiration Date for each production run. With our existing labels, we could not

make these changes easily.”

|

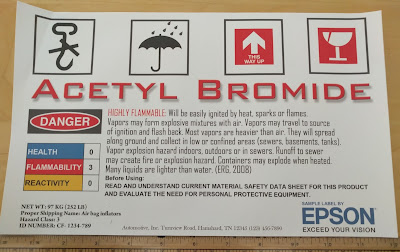

| Existing Shakti Label |

|

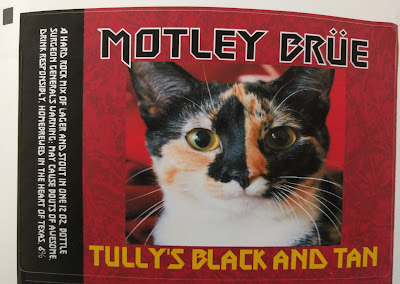

| Existing Shakti Back Label |

To improve their label production

process, Shakti purchased a C3500, rewinder, and waterproof, matte poly,

die-cut labels. To change their label

design, Shati asked Color Label Solutions to assist.

For the Shakti redesign, our graphic

designer Tony Molina had three key issues to consider:

- Creating full-bleed effect on the color bands on the labels

- Adding the fillable forms for the enjoy by date and lot number

- Insuring the barcodes would scan

When asked, “what are the most

important elements of a label design”, Tony says, “I don’t have a set of rules

specifically. However, I consider the

coloring of the actual product or container.

It’s important to insure the label stands out and communicates the key

attributes and positioning of the product.

I create graphics or images using a variety of software tools; and

select fonts to enable buyers to read the label up close as well from a

distance. For Shakti, we had a design

template; we just needed to update the label to print on the C3500.”

To print full-bleed, Tony created the actual sized

document in QuarkXPress. Then he

manually create the bleed by extending the color or graphic element outside the

edges of the document, normally by 1/16 of an inch.

|

| New Shakti Label with Full Bleed |

|

| New Shakti Label With Full Bleed |

With this setup, you just print in Reader selecting “actual

size” to get the full-bleed effect on your specific die-cut label size.

To create the forms, we use Acrobat; making it easy to

convert a label to a form fillable PDF.

On the barcode, however, we had to be careful with

size. As the C3500 has less print

resolution than a printer typically used by a printshop, smaller barcodes may

not scan properly. To produce small

barcodes, Window-based, lower resolution printers may not create small lines

sufficiently “straight”; disrupting the spaces between the lines and thus

scanning. For Shatki, we needed to

increase the barcode size from the original design to insure they scanned

properly.

Once the label was redesigned and the printer was setup,

Shakti was printing and rewinding labels to place on their applicator.

After this first label project, Ryne says “We are very happy with the

printer and applicator decision as it gives us the ability to change labels

quickly. Also, we’re excited that our labels are now

waterproof and smudge proof.

Now Shakti not only has great tasting beverages, but also a

label printing process that is much easier to do. If you need a label redesign and/or a new

labeling process, contact Color Label Solutions. We’ll make sure your labels look great and

are easy to print.

Guy Mikel

855-962-7670