|

| LCX603 |

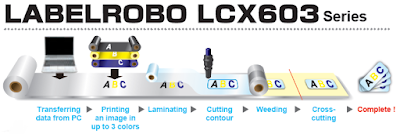

Recently, I met with the Graphtec Digital Solutions team to learn about

the LCX603; the all-in-one, 3 color thermal transfer printer. This device prints utilizing 3 thermal

transfer ribbons, laminates, die-cuts, weeds (removes the matrix), and cuts off

a sheet of labels.

|

| LCX603 Processes |

And it produces beautiful, durable labels appropriate for the end of an

assembly line.

|

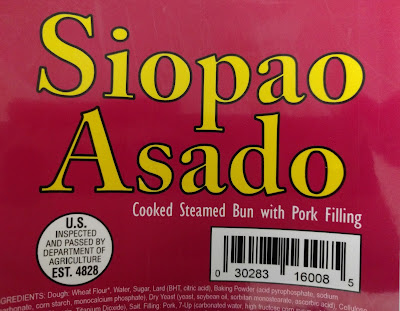

| LCX603 Labels |

According to Brian Malouf, in Sales for Graphtec, “I see three key

features of the LCX603 printer. First,

the printer produces labels in 3 different colors, using thermal transfer

technology. Adding colors to labels in

manufacturing increases attention, improves recall/recognition, and decreases

errors.

Second, the printer produces high quality, small fonts and barcodes using

thermal transfer print heads capable of higher than normal resolution; up to

600 x 1200 dpi. These type of labels are

perfect for an electronic manufactures who need a set of labels to apply to an

assemble product at the end of a production line.

Third, the device prints, laminates, die-cuts, and weeds in one step;

everything required to produce durable, colorful labels. The sheet produced by the LCX603 are perfect

for barcode, caution and warning labels including UL.”

|

| LCX603 |

The LCX693 comes with a Windows driver that controls the colors and

cutting of the labels.

|

| LCX603 Driver |

According to Brian, “Each color used in the label file must

be assigned to a corresponding print head, or channel. In this example,

yellow is assigned to channel 1, where we have a yellow ribbon loaded.

Blue is assigned to channel 2 where we have a blue ribbon loaded. Black

is assigned to channel 3 where we have a black ribbon loaded. Green is

assigned to both channels 1 and 3, so anything green will receive a bottom coat

of yellow, followed by a topcoat of black.

Brian continues, "We offer 7 colors of ribbon in

“semi-resin” or resin: red, orange, yellow, green, blue, black, and white.” In addition to the ribbons, Graphtec sells 14

different label media and 6 different laminates to use in the printer.

From my perspective, the key benefit of the LCX603 is the ability to

produce a multi-color, durable set of labels on-demand. With this device, electronic equipment

companies or manufacturers of products requiring warning signs can now produce

a set of labels required for each step in their production process

on-demand. A set or sheet of labels

costs $0.50 to $0.80 for the actual label and ribbons. No longer must manufacturers purchase a large volume of expensive preprinted labels. They can just produce exactly what they

want, when they want, each time enabling design changes or new variable data until printing.

|

| LCX603 Ribbon Holder |

As for watchouts, I see three.

Initially, my thought was the LX603 printer is complex; with all the

steps involved in producing the final label.

This complexity may make this device difficult to set up and keep

running. To help with this potential

watchout, Graphtec provides on-going support for the printer.

|

| Die Cutter |

In addition, the printer is relatively slow. It takes from 30 seconds to 1 minute to

produce a sheet/set of labels. But you

could have many different small labels on this sheet; ready to apply.

Lastly, the LCX603 is relatively expensive at approximately $15,000+;

plus branded, approved consumables. At

250 sheets of labels per day (approximately 4 hours) for 250 days per year for

5 years, the hardware cost of a sheet of labels would equal approximately

$0.05/label. With the hardware added, the total cost per sheet of labels could

add up to $0.55 to $0.85. But this sheet could provide all the small, durable

labels required for a piece of equipment.

Watch the LCX603 produce labels here:

According to Graphtec, over 200 of the LCX603 printers have been sold

to a variety of manufacturers in Japan.

I appreciate your feedback on how this printer would fit in your

operation. Contact me to discuss how this

all-in-one printer of durable, colorful labels would work in your operation.

Guy Mikel

855-962-7670