|

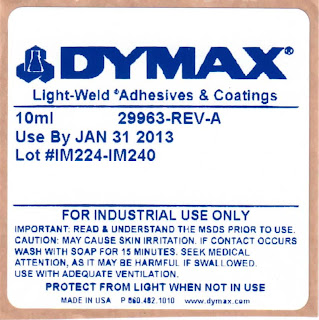

| Scan of Not Finalized Label |

http://colorlabelsondemand.blogspot.com/2012/03/what-h-is-ghs-opportunity.html

After selecting the printer, Dymax had to find media that worked in the

color label printer as well as met their aesthetic requirements. Prior to needing to comply with GHS, Dymax

used thermal transfer printers using blue ribbons to produce their labels.

As an international company that produces labels

in 17 different languages and sells products into a large number of countries,

meeting the GHS requirements is very complex project. According to Alison

Jeannin , Regulatory Specialist for Dymax, “we use software

from The Wercs (www.thewercs.com) to produce the content for our labels. However, we needed to find other components,

including printers and media, to produce the total GHS solution. As a goal, we decided to have our GHS

solution in production by the end of 2012.”

To build their GHS solution, Dymax started the process last

November by looking for a color label printer.

During their review, Dymax look at a large variety of printers,

including some costing thousands of dollars.

According to Alison, “our IT managers led our search, insuring we

purchased printers that met all of our requirements, including network

capability, on-going maintenance, and global support. With operations in the US , Germany ,

Korea and China , we needed an

Ethernet-capable color label printer from a company with a worldwide

presence. Based on the review and our

specific requirements, we selected the Epson TM-C3400.”

Initially, Dymax tested media from a source I

recommended. Although suitable, it had a

slightly different face stock color from their existing stock. Based on this difference, Dymax worked with

their existing label vendor to find material that matched their existing stock,

yet worked in the TM-C3400. According to

Alison, “the process to select our label media has taken longer than we originally

expected. Although we still need to

decide whether or not to use die-cut or continuous media, we have media that

meets our requirements for GHS labels. ”

After selecting the print and media, Dymax needed to

integrate the Wercs Software. “Although

Wercs provides all of the text, symbols and icons required, we need to add

variable data to each GHS label, including lot number and expiration date. Our IT team built an interface that

enables us to add this information manually just prior to printing.”

|

| Scan of Not Finalized Label |

Now that the basic solution is

selected, Dymax still has a lot of work to do to implement the solution. Alison says, “Although following the GHS

requirements, different countries have slightly different requirements and

timelines. For example, the EU, Australia , and Korea all have different label

content and formatting requirements for their labels. China requires a border on the outside of

their GHS labels on product shipped into their country; but will allow black

pictograms for labels on internally produced and shipped products. And it seems the United States will move to meet the

GHS requirements by July 2015.” To meet

all of their various worldwide requirements, Dymax will build a GHS “Cell” on

their factory floor. This cell approach

will enable them to meet the various requirements when needed.

At the end of our discussion, I

asked Alison what was the one thing she learned by going through the complex

process to implement GHS labels.

Laughing, Alison said “be nice to IT co-workers and ask for favors

sparingly.”

Learning about the implementation

at Dymax, its clear moving to GHS labeling is a complex task. But Dymax has built an elegant solution that

meets the compliance requirements as well as their needs.

No comments:

Post a Comment