Recently, one of our customers inspired us to look into a set of

interesting applications:

Color-On-Wheels.

|

| Color-On-Wheels |

I’d like to describe in this post possible applications and their

benefits of moving a color printer to label at the point of activity.

Newcastle Systems is an innovator of workplace mobility solutions for

many of the world’s leading retail and operations companies. As the leading

provider of Mobile Workplace© solutions, Newcastle Systems provides the means

to dramatically improve employee and facility productivity without major

changes to your infrastructure, software or processes. A Newcastle Systems’ Mobile Workplace© facility

requires less equipment and less power to do the same work as a standard

workplace configuration.

According to Kevin, moving the printer to the point of activity is a

key part of “lean” and “process improvement”.

Kevin says “mobile work stations enable organizations to label at the

point of activity. It makes no sense to use handheld computers and cell phones in manufacturing plants and distribution centers; but have printers remaining

static and fixed. It’s time to change

this mindset. This process improvement step saves time and reduces or

eliminates labeling errors." This

process improvement idea can be used for many applications; let me discuss a few here.

To me, the most obvious color labeling application is Finish Good

Labeling, especially with large items such as chemical drums or mini-bulk

tanks. Typically, this type of

manufacturing operation would print labels in batches and then take the labels

out to the shop floor to apply them to the finished products. However, it would be easy to apply the

labels to the incorrect finished goods, creating a potentially serious issue or

at least a return item. By moving printing to the point of application, you

eliminate the costly steps/time to and from the printer but also reduces or

eliminates labeling errors. Further this

process eliminates the inventory of preprinted labels kept in inventory.

Newcastle has produced an interesting case study featuring Grant Industries. Contact me to get this PDF or download the study here: https://www.newcastlesys.com/finished-goods-labeling

And

if you are applying paper labels to large items, you might find this earlier

post on proper label application of interest:

Another possible application for Color-On-Wheels is in Receiving. Most manufacturing facilities will print

labels in a central location, and then take them to the dock for application,

wasting a significant amount of time and effort. Newcastle shows this wasted time/labor in

this illustration:

By adding color codes to this mix, you can improve the accuracy of both

put away and picking. And

with label creation software, you can automate the selection of a color for

each area of the warehouse.

In addition to color codes, you can add images

to the pick tickets to improve the accuracy of this error prone

step. In one of my first ever posts, I

wrote about Marco Specialties use of images to improve picking:

Further, you can use Color-On-Wheels application to apply replacement

brand labels when OEM products are received. Relabeling while receiving reduces or

eliminates potential errors later in the warehouse or during shipping.

In addition to Finish Goods and Receiving,

manufacturers should consider using Color-On-Wheels for Work-In-Process

Labeling. At some plants,

work-in-process inventory/QA Testing requires labels to be applied to describe

the status of the inventory (i.e. quarantined).

Here is an earlier post on this application of color labels. https://colorlabelsondemand.blogspot.com/2014/09/work-in-process-color-labels.html

Typically, these labels are printed or stored in a central location and

the operator walks to/from the inventory location to apply. With Color-On-Wheels, you can move the

printer to the point of work to reduce or eliminate errors as well as save time

and labor.

Shipping is another popular application for powered carts;

printing both the shipping labels and documents.

|

| Mobile Shipping Cart |

With mobile carts, you can process orders at the pallet, increase

shipping accuracy and remove wasted time and motion. By adding color to the staging process, you

can increase the accuracy of deliveries as well by color coding the shipping

labels during staging:

|

| Color Coded Shipping Labels |

|

| Color Coded Shipping Documents |

A very long time ago I worked on a case study of Tubelite and their

shipping process: https://colorlabelsondemand.blogspot.com/2014/09/work-in-process-color-labels.html

According to Kevin, “very few companies use color in their shop

floor and warehouses. But it seems to be

an easy way to add efficiencies to the processes in these important areas. Plus, you can use existing wireless networks, software and

hardware (may need to add a color label printer) to enable workers and improve

process flow.”

And for the cannabis market specifically, I

describe how mobile work stations can improve growing operations in this recent

post:

If you can imagine the possibilities of “Color-On-Wheels”, contact us

to discuss how combining color label printers and a mobile power cart from

Newcastle Systems can improve the operations of your business.

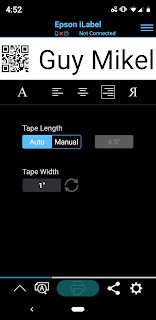

Guy Mikel

855-962-7670