In addition to repackaging, Prescript offers a dispensing

solution called 5MRX Dispensary.

According to Bill Hartig, President of Prescript Pharmaceuticals, “5MRX

Dispensary is a complete dispensing solution, from small physician offices to

large pharmacies. Traditional dispensary

methods are inefficient, taking lots of time and space. Plus these methods introduce potential errors

into the dispensing and labeling process.

With our new dispensary solution, we eliminate the potential for

dispensing errors.”

5MRX Dispensary includes the software application,

Dispensary. The Dispensary software application allows you to track

and trace new prescriptions & refills; order, receive, dispense, and

transfer filled pharmaceutical vials; and import/export data for reports,

including controlled substance submissions.

In

addition, the 5MRX Dispensary includes modular, stackable and lockable storage

containers:

as well as revolutionary, new m-pack® pharmacy vials from M-Pack Systems (www.mpacksystems.com).

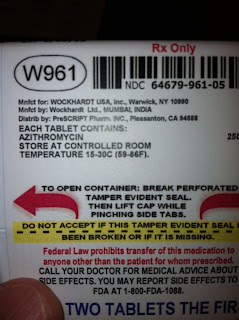

The

m-pack’s flat design features 1.8X label space, allowing for the opportunity to

communicate more important information in larger type sizes on an easy to read

flat surface. According to Bill, “with

the m-pack vial, you can use much larger labels than traditional round vials. Larger label real estate allows for bigger

fonts, color images, highlights in color and QR Codes to communicate important

information to the end user; reducing potential errors further. Plus, m-pack flat shape is 1/3rd more space

efficient than an equivalent round vial; and is stackable, rackable and

shippable making prepacking much more effective.”

With

the larger label size, the Dispensary solution is perfect for print on-demand

color labels. Bill recommends the Epson color

label printer for pharmacies to print m-pack vial labels when required at the

point of service. See Bill’s label

design including the pill image with number.

Prescript

Pharmaceuticals sells the hardware (storage containers, etc.), and licenses the

software for a monthly fee.

After

seeing this solution, one key point has become clear to me: Combining the larger labels on the m-pack

vial with software from companies such as Prescript Pharmaceuticals will make

print on-demand color labels the industry standard in pharmacies in the very

near future. Contact me if you want to

discuss how you or your customers can deploy a print on-demand color label pharmacy

solution.

Guy Mikel

guy_mikel@colorlabelsolutions.com

.jpg)

.jpg)