Jon contacted us when needing a labeling process that would fit their

POS system and food preparation process.

According to Jon, “we need a printer that can produce color labels

affordably and easily as well as in variable lengths. We’ve been using Avery sheet-fed labels and a

desktop printer; but find it difficult to do what we want.”

|

| Sheet Fed Labels |

Jon continues, “As we sell many different items, we don’t want to use

preprinted labels. Also, we like to use

Kraft paper if possible as it would match our containers. Finally, we’re moving to a new point of sale system (POS); and need

the printer to work with this system.”

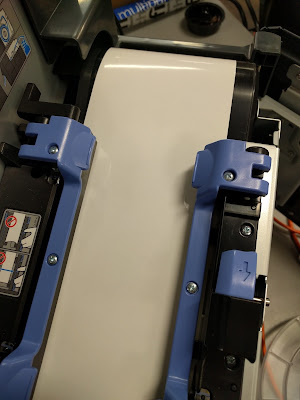

After speaking with Jon, I recommended the C3500; especially given the

printer can cut labels in variable lengths.

To help Jon decide, I printed and sent samples, even on Kraft paper, as

well as determined the estimated ink costs.

For one of the basic round labels, I estimated the ink cost at

$0.014/label.

|

| C3500 Estimated Ink Cost |

For the 15” label, I estimated the ink cost at $0.051/label.

|

| C3500 Estimated Ink Yield |

Based on the label samples and estimated costs, Jon purchased a C3500

printer and labels. After working with Tim,

our Support Manager, Jon was printing labels quickly and easily; sending me a

picture of his first label printed on the material that comes with the C3500.

|

| C3500 Printed Label |

Unlike most customers, the real work for Jon started after he was

printing labels. Jon needed to make sure

label printing fit into the processes and systems he wanted to put in place.

Continuing, Jon says, “We built a process using our new POS. Each day, we select in our POS system the

items/labels we need to print for the various orders. For example, one order may have 10 different

items. Based on the items selected, the

POS system produces a PDF using the variable images and text in our database. Each page of the PDF becomes one of the

inner:

|

| Package Inner Label |

Or outer labels:

|

| Package Outer Label |

of the item in the order. Each label is automatically cut based on the

page length; the Color Label Solutions support manager Tim showed us how to

select this setting. No longer do we

need to select multiple labels from sheets; we just apply the labels printed

for each order picked. I LOVE THIS PRINTER; it’s perfect for a small business like ours.”

|

| C3500 Label |

Learn more about Good Heart Catering's community participation here:

The story of Good Heart Catering is very gratifying for me on several

levels. First, we helped a new customer

start printing color labels on demand.

Second, we helped a small business develop and implement an outstanding,

highly productive new process that saves time and money. Lastly, we supported an organization

committed to the greater good of their community.

If you want to create or improve your labeling process, contact

us. Hopefully, you’ll love your printer

too!

Guy Mikel

855-962-7670

info@colorlabelsolutions.com

Purchase the C3500 Here: https://colorlabelsolutions.com/product/c3500-inkjet-label-printer/

Purchase the C3500 Here: https://colorlabelsolutions.com/product/c3500-inkjet-label-printer/