After selling, installing and supporting thousands of label printers, I

say 95+% of them are utilized in manufacturing/producing a product label. So

this post is different; it’s about using label printers to produce a handmade,

unique commemorative item - Or what I call, “Fun with Labels!”

Recently, our neighbor, Carrie, asked if I would produce labels for her

project. And of course I said yes; but

wanted to know more about her plans.

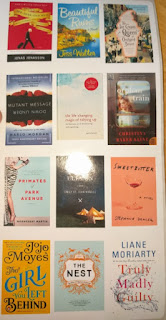

It seems she wanted to produce something special for her book club. According to Carrie, “our book club has been

together for more than 8 years. And this

year, I just happened to be hosting our December meeting. Given it was the end of the year, I wanted to

make something special for our club that commemorated the books we’d read. I checked Pinterest; and found

only different bookmark ideas. Given

that many of our club members use e-readers, bookmarks seemed out-of-date. So, I decided to make an ornament with book

cover images of the books we read January thru December.”

To start the project, Carrie cut a block of wood into cubes using her

miter saw. “For about $15, I got a nice 3’

x 2.5” piece of wood that enabled me to cut out 12 cubes. After cutting the wood, she sanded the wood

using sandpaper to smooth out the edges.

Once the blocks were finished, Carrie went online to get the images of the

books. Initially, she tried to print the

images on her desktop printer; but was unhappy with the results. Given she knew I was in the label business,

she asked me to print labels for her.

After listening to her requirements, I suggested she create a 4” x 8”

PDF containing the highest resolution book cover page images she could

find. I suggested 4” x 8” size as I had

this size available in a glossy paper label making it easy to print.

|

| 4" x 8" PDF With Images |

It would have been easier if we would have created individual smaller

labels printing one at a time; but you would need to have the correct sized

images and labels to make this work correctly.

I printed 12 labels, each containing the set of images representing

each of the books read during the year.

|

| 4" x 8" Gloss Paper Label |

Carrie then cut the individual image labels and applied them to the

blocks including a special message on the bottom.

Then, she coated the block with an acrylic sealer to protect and give

it a shine.

Finally, she drilled a small hole in the top, added gorilla glue in the

hole, and forced the knot on the string holding the loop/bow into the hole. And

Voila, Carrie has produced a beautiful holiday ornament for her club!

|

| Hand Made Commemorative Using Labels |

According to Carrie, “I got great feedback from our book club

members. In fact, my girlfriend said she

wanted one every year! I think the size

of the block and book images were just perfect; not too big or small.”

|

| Hand Made Commemorative Using Labels |

After completing the project, Carrie says, “Pictures would be a good

idea as well; your kids, grandchildren, etc. to commemorate any event. The labels with the images made it easy to

do!”

Carrie is crafty and creative; and a great neighbor. And using Carrie’s idea, you can turn the

labels printers in your plant or office into your own personal handy-craft

tool; a “Fun

with Labels” opportunity.

Contact us if we can help you with any of your label needs.

Guy Mikel

855-962-7670