This week, we received our new

LX2000 color label printer from Primera.

With up to 4,800 dpi, from .75” to

8” print width, durable pigment ink, built in cutter and BarTender driver, the

LX2000 offers a great solution for those customers who want to print high

quality, full bleed, relatively low volume labels.

|

| LX2000 |

Let me tell and show you why the

LX2000 does a good job for this type of manufacturer.

To

start using the LX2000, I download the instruction manual and driver here: http://www.primeralabel.com/support/LX2000.html

When I downloaded the driver, I

learned of my biggest disappointment with the LX2000. I was told by Primera that a Mac driver would

be available. Instead, I read this

statement:

The LX2000 is not currently

compatible with Macs.

This was disappointing as I had a

customer waiting for the LX2000 specifically for the Mac driver. Bummer.

Although no Mac driver, I did

learn about the wireless option:

Wireless is a unique feature I believe.

And the BarTender driver:

As I use BarTender frequently, this feature as a real benefit.

After installing the driver, I

loaded the ink cartridges. The black is

larger than the other three cartridges.

|

| LX2000 Black Cartridge |

|

| LX2000 Cyan Cartridge |

The

cartridges seemed small given the manufacturing aspect of this printer. Plus I find it interesting that Primera does

not change the ink cartridge casing, just like VIP 495: http://colorlabelsondemand.blogspot.com/2015/05/495.html

During setup of the driver, I

realized that the printer required alignment of the printhead; just like many

desktop inkjet printers do. To align the

printhead, you need to load A4 paper, provided by Primera, into the printer.

It took me 3 tries to get the

alignment to work correctly. I decided

that I had not pushed in the paper sufficiently far. Be sure the paper is gently pulled into the

printer when loading.

After aligning the printhead, I “attempted”

to print labels. Frankly, I had a rough

start. First I had labels that were

banding.

I have no idea why; or even why

it stopped. But it did.

Second, the printer “grasped” the

skin on my hand and pull it into the roll arm.

Ouch!

Be careful when loading the labels;

and make sure the lever is up on the Roll Guide

And third, some jobs would just not

print:

By the end of the day, I decided

all of these issues were operator error.

Specifically, you need to insure the paper is loaded correctly; and to

understand the button push sequence. It’s

not obvious what the buttons and lights mean when flashing. Be sure to read section 5H on buttons/LED

lights. And be careful of the rotating

and unprotected arm.

Even with these issues, I was soon printing great looking labels full bleed on matte paper:

|

| LX2000 Matte Paper Labels |

Gloss paper:

|

| LX2000 Gloss Paper Labels |

Kimdura poly labels:

|

| LX2000 Kimdura Poly Labels |

And even clear polyester film:

|

| LX2000 Clear Film Labels |

Primera did a great job of

explaining how to print full bleed labels in section 4E of the manual. With BarTender, they have made full bleed

printing easy to do.

In terms of waterfastness, I

found both the Kimdura and clear film performed well. However, alcohol removed some of the ink from

the Kimdura label (see the slight red over the barcode):

|

| LX200 Alcohol Effect |

In addition, I printed die cut, blackmark and continuous labels. All printed correctly with the appropriate

settings.

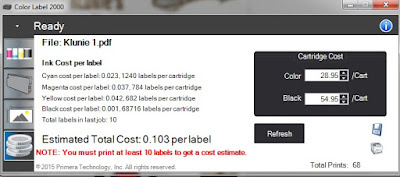

One nice feature was the ink cost

analysis in the Status Monitor. As a

worst case, I printed 10 (according to the Status Monitor, 10 prints is the minimum

required to print for an accurate cost analysis) 4” x 6” high gloss labels at

the highest resolution.

Ink for these labels cost $0.107

and took 26 seconds each. $0.11 is a

seemingly high ink cost. But the label

print quality was great!

|

| LX2000 Ink Cost/Label |

After discussions with Primera, I printed a second label, 4" x 6" matte poly at normal resolution with less than 100% coverage to see the ink cost. The label printed really great!

And the cost per label was $0.10; about the same price.

To purchase the LX2000, contact us or visit our store: http://stores.colorlabelsolutions.com/lx2000-color-label-printer/

To purchase LX2000 ink: http://stores.colorlabelsolutions.com/lx2000-ink/

And don't forget to purchase 3 years of "Hot Swap" Extended Warranty: http://stores.colorlabelsolutions.com/lx2000-hotswap-extended-warranty/

|

| LX2000 Print |

|

| LX2000 Cost Per Label |

To purchase the LX2000, contact us or visit our store: http://stores.colorlabelsolutions.com/lx2000-color-label-printer/

To purchase LX2000 ink: http://stores.colorlabelsolutions.com/lx2000-ink/

And don't forget to purchase 3 years of "Hot Swap" Extended Warranty: http://stores.colorlabelsolutions.com/lx2000-hotswap-extended-warranty/

Overall, I believe the LX200

produced great looking, full bleed labels easily. For manufacturers with relatively small

volumes that want high resolution labels, the LX2000 seems like a good

choice. Please remember: no Mac driver

currently and relatively high ink cost is a part of using this label printer.

Contact us to learn more and to purchase the LX2000 printer, ink and labels.

Guy Mikel

855-962-7670

#colorlabels